Warman Design and Build Competition 2023

Feb 2023 - Jun 2023

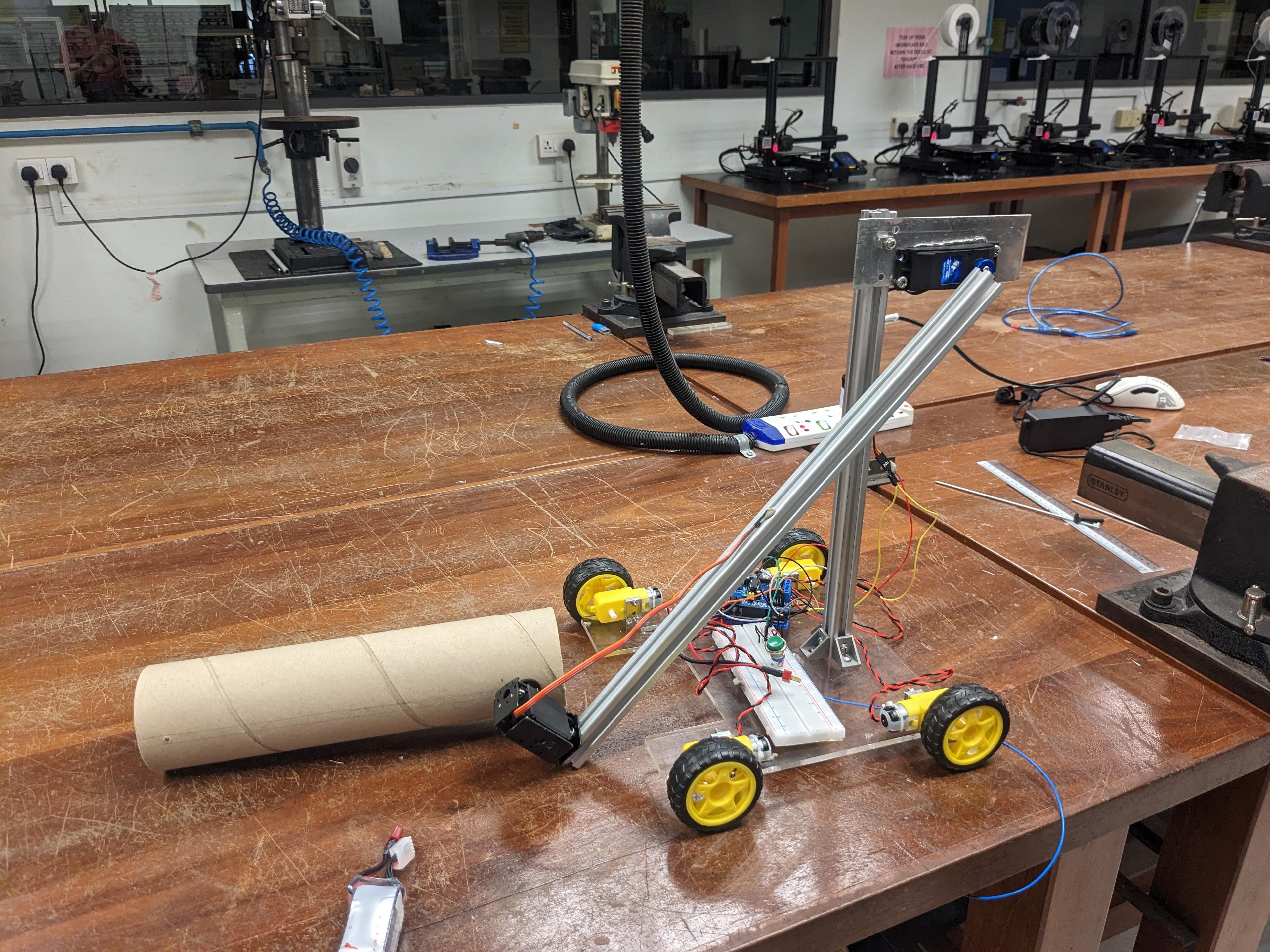

Picklesaurus - our entry into the 2023 Warman Design and Build Competition that had us design a robot to collect and deposit fuel and oxidiser fully autonomously.

The Warman Design and Build Competition is an annual contest open to teams from universities around the world. Organised by Engineers Australia and sponsored by Weir Materials, the competition sees Mechanical and Mechatronics students design and build a robotics solution over 6 months. During my exchange to Kuala Lumpur, Malaysia in 2023, along with 3 other colleagues, I competed in the 2023 Warman Design and Build Competition and ultimately placed 1st runner-up at the campus competition.

Project REFUEL: The Problem

In the fictional world of Gondwana, inhabitants utilise hybrid propulsion engines powered by liquid fuel and oxidiser stored in spherical vessels. A recent near-miss incident highlighted the risks associated with mishandling these vessels, leading to the redesign of storage zones to ensure strict separation between fuel and oxidizer containers. The task for student teams was to design and build a scale demonstration system capable of autonomously collecting three fuel vessels (simulated by tennis balls) and three oxidizer vessels (simulated by squash balls) from their respective drop zones and depositing them into the correct storage silos without any contact between different types of vessels.

Design Constraints

All teams were required to adhere to the following specifications:

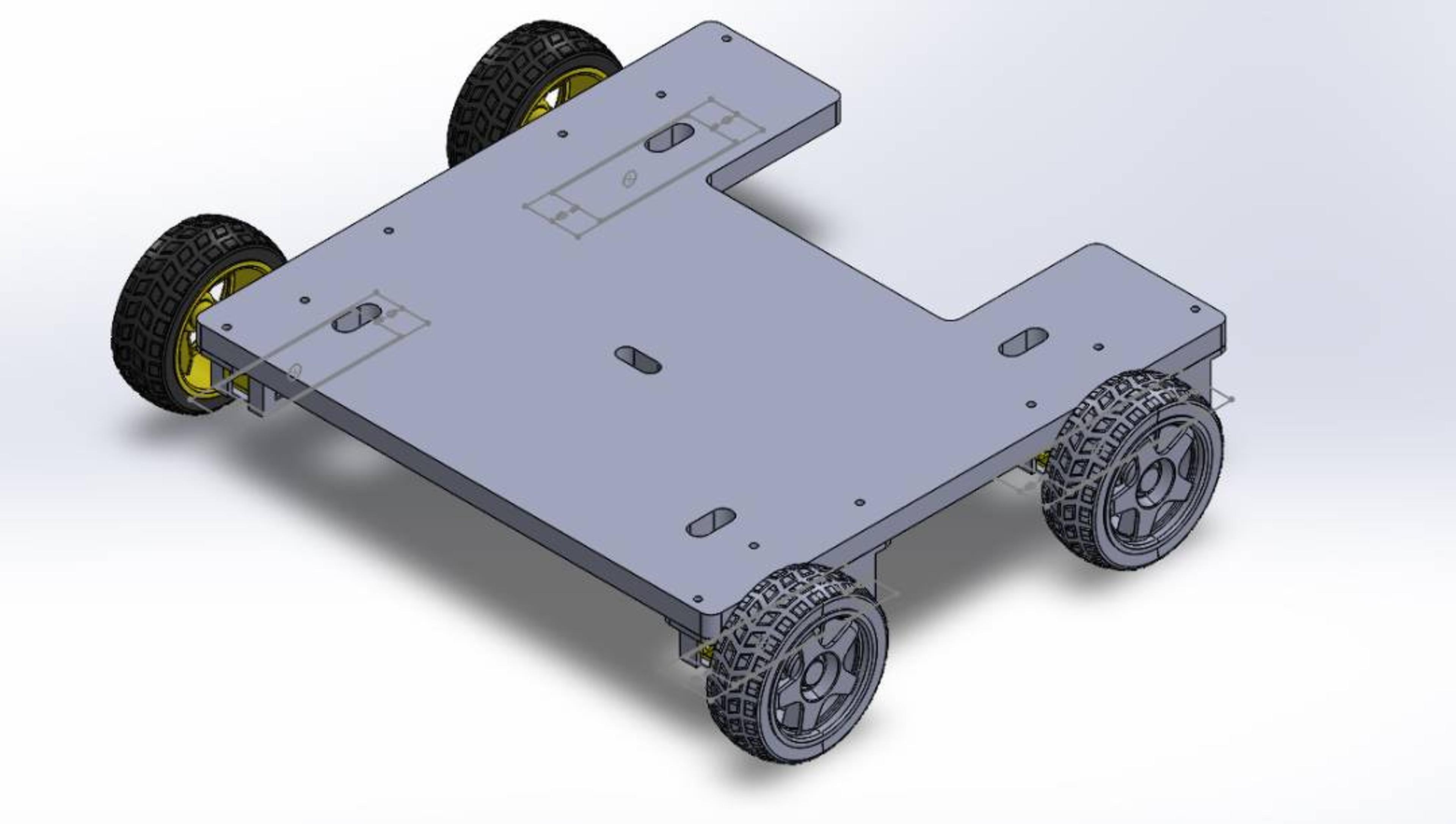

- Size and Weight: The system must fit within a 400 mm³ cube and weigh no more than 6 kg.

- Autonomy: The system must operate autonomously, requiring no human intervention or control during the task.

- Safety: The system must prevent any contact between fuel and oxidizer vessels at all times.

- Performance: The task must be completed within 120 seconds.

- Safety and Compliance: The system must not damage or contaminate the competition track or vessels.

The full rules and specifications are available on the Warman Design and Build Competition Website.

Our Solution: Picklesaurus

Our submission to the competition was an autonomous robot with a triple-jointed robotic arm. The arm was the most complex part; requiring a powerful servo with enough torque to lift the whole weight of the arm when fully extended and loaded. While it certainly would've been easier to use a double or single-jointed arm, to fit within the space constraints of the competition, we needed the robot to be able to fold itself into a very compact shape for transport.

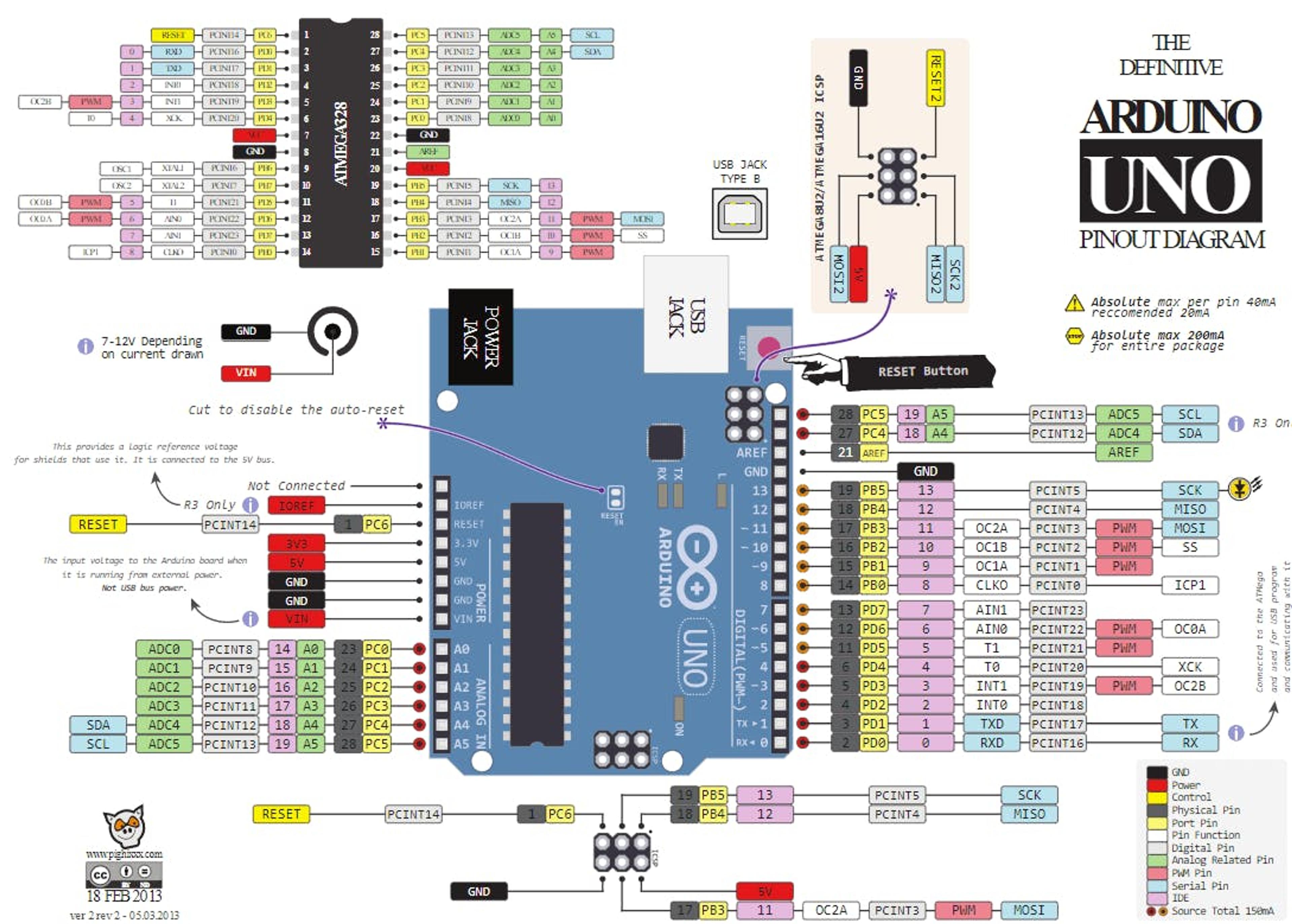

Throughout the competition, my primary focus was our robots microcontroller, the brain of the robot. We used the common Arduino Uno board with a high power shield and relays to interface with the various sensors and motors. I worked on our sensing and actuation system; taking readings from the onboard compass and ultrasonic sensors, then translating that into actions; voltages sent to our servos and linear motors. This included writing two libraries to interface with both the wheels and movement system more declaratively. Instead of requiring control over each individual motor or servo just to turn or adjust the arm position, these common functions were presented as simple declarative APIs such as wheels.forwards() or arm.move(ARM_UP, 1000). This enabled rapid testing and prototyping, with our time and mental effort no longer spent on writing precise voltages to specific pins.

As is the spirit of the competition, the source code for this project is available on GitHub.